Finding proper construction materials is crucial as they can have a significant impact on the final outcome of the structure. Concrete is one of the most widely used materials in construction today and therefore, understanding the different types of concrete is vital. Prestressed concrete and reinforced cement concrete are two such types with reinforced longitudinal and transverse steel bars (rebars). Read on to learn about the properties and differences between these two types.

Prestressed Concrete

What is Prestressed Concrete?

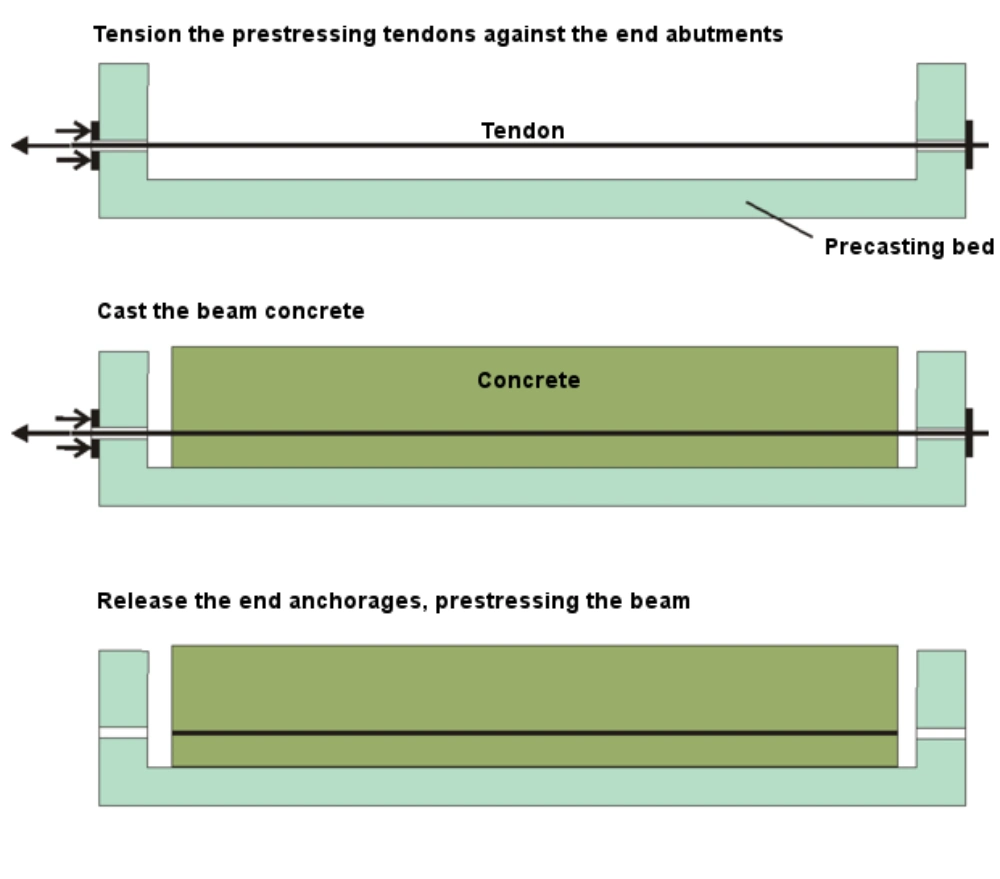

Prestressed concrete is made by placing high-tensile steel tendons in a particular form and both ends are stretched while or after the concrete is poured. Prestressed concrete is usually formed under stress and provides a great degree of strength. This type is the most preferred choice for large projects and commercial buildings with high load bearing requirements. Pre-tensioned concrete, bonded post-tensioned concrete and unbonded post-tensioned concrete are a few categories of prestressed concrete.

Pre-Tensioned Concrete

This is a type of concrete where tendons are strengthened before the concrete is cast to create a bond between two materials. This prevents corrosion of tendons and has longer life spans and crack resistance.

Bonded Post-Tensioned Concrete

In this type, the concrete is poured before the tendons are tensioned or strengthened. When the concrete cast becomes hard, the tendons are tensioned with the hydraulic jacks. The tension remains after the jacks are removed and pressure is transferred to the concrete.

Unbonded Post-Tensioned Concrete

In this method, plastic and metal ducts are placed in the form and then the concrete is poured. After this, the tendons are inserted allowing them to stretch to applied tension. Later they are anchored at ends to resist the tensile force.

Advantages

- The use of thinner and lighter prestressed concrete results in lower self-weight and proves to be economical in the overall construction process.This makes it suitable for heavily loaded structures.

- Prestressed concrete provides enhanced durability as it doesn’t crack and rusting is minimised.

- It is suitable for structures that are exposed to vibrations and shocks like bridges and dams.

- It has high resisting capabilities, particularly to strong forces.

- Prestressed concrete involves low maintenance costs.

Limitations

- Prestressed concrete often requires more supervision and quality control.

- The materials used to create prestressed concrete are specialised and more expensive.

- The use of high-tension steel makes the prestressed concrete sections more brittle.

Reinforced Cement Concrete

What is Reinforced Cement Concrete?

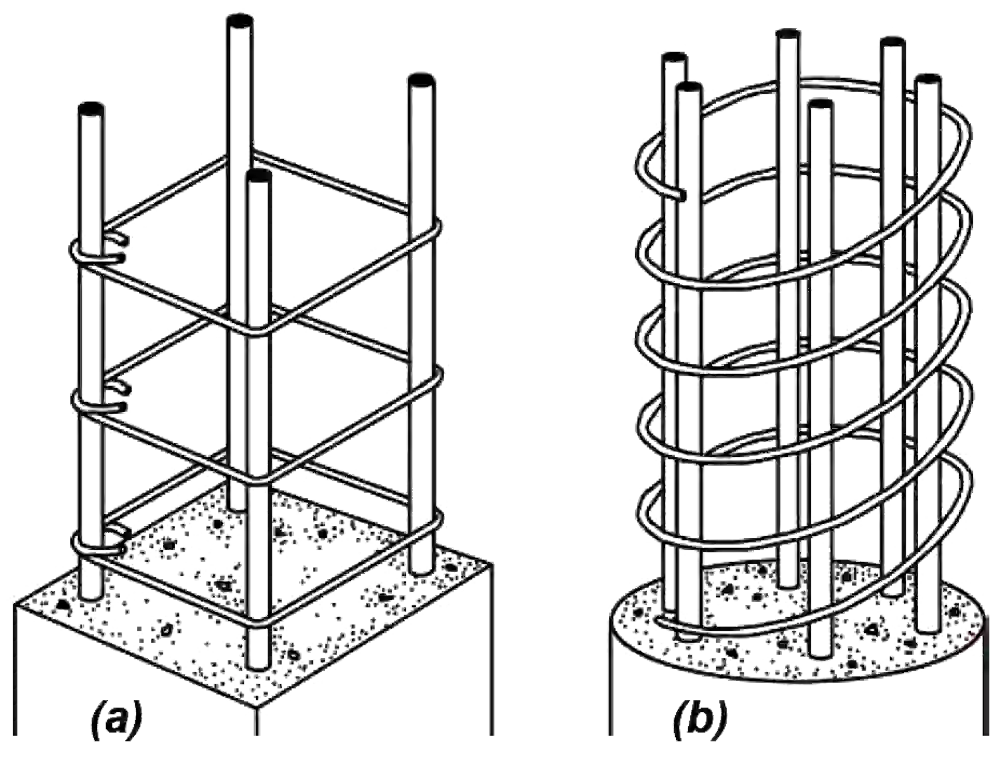

This is the most widely used material in construction. Steel bars are placed into the formwork before the concrete mix is poured and evenly distributed. The custom form allows the constructor to choose between conventional and unconventional shapes. This creates opportunities to get creative in the architecture of the structure. Beams, bridges, dams, foundations, highways and sidewalks are the most common areas where reinforced concrete is used. It is often indispensable in modern construction for its ability to absorb compressive forces.

Advantages

- Compared to other construction materials, reinforced cement concrete has a higher compressive strength.

- As it is in the form of liquid in the initial stage, reinforced concrete can be moulded into desired shapes and forms, making it suitable for creative architectural applications.

- It has good fire and weather-resistant capabilities

- It is considered the most economical construction material for building dams and piers.

- Reinforced cement concrete requires less skilled labour to build a structure as the process is less complicated.

- It is more durable when compared to other construction techniques.

- The cost of execution and maintenance is low when compared to prestressed concrete.

Limitations

- Shrinkage in reinforced concrete leads to cracks and weakness in the structure.

- The process of reinforced concrete involves mixing, casting and curing. All the steps need to be carried out with precision to achieve a strong and durable structure.

- While reinforced concrete is strong in compression, it is weak in tension.

- Usually, the reinforced concrete structures are heavy and bulky making it less suitable for lightweight applications.

- It may be susceptible to corrosion and also prolonged exposure to heat can weaken the concrete.

Differences between Reinforced Cement Concrete and Prestressed Concrete

Aspect | Reinforced cement concrete | Prestressed Concrete |

| Fatigue limit | The fatigue or maximum stress limit is low | The fatigue limit is high. |

| Deformation | The deformation when subjected to tension in the future is more | The deformation is comparatively less. |

| Material cost | The cost of material involved in the process is low | The cost of material involved in the process is high |

| Materials used | Mild steel reinforcement bars are used in the process | Tendons made from high tensile steels in the form of single or multi-wired strands are used in the process |

| Internal stress | No internal stress is induced in the process | Internal stress is induced in the process before loading. |

| Dead load | The dead load is comparatively high | The dead low is comparatively low |

| Quality control | Requires basic quality control and supervision | Very high-quality control and supervision is required during the process. |

| Special techniques | Does not involve any special techniques | Special techniques and equipment are involved, especially to anchor tendons and apply tensile stress. Extremely skilled labour is vital. |

| Testing of steel | There is no way to test the steel in this method. | Steel can be tested before the placement. |

| Steel corrosion | Steel corrosion is a possibility in this method | Steel corrosion is negligible comparatively. |

| Application | Most commonly used in the construction of commercial buildings | Most commonly used in bridges, railway sleepers and dams. |

| Brittleness | It is less brittle | It is more brittle |

| Tensile strength | Has good tensile strength | Has very high tensile strength |

Selecting the right type of material for construction depends upon the specific needs of the process like cost, structural requirements and performance. When it comes to choosing between reinforced cement concrete and prestressed concrete, one needs to understand the properties and applications of both. To build a durable, efficient and cost-effective project, it is imperative to carefully study and leverage the materials appropriately. It is advisable to consult structural or civil engineers to recommend the most suitable type for your project.